|

On this page:

Religiously changing your oil on the Rialta engine is the best

thing you can do for it. It is not much different than changing oil on any other

motor vehicle. As with many newer cars, there is a sheet metal "belly pan" that

should be removed to gain access to the oil filter. This pan is not heavy and can

easily be maneuvered out of the way by one person. Make sure you use a new filter

and o-ring at every oil change.

Oil Change Tools & Equipment:

¤ - Ramps

¤ - Tools:

- Large Crescent-type wrench or suitable gripping tool

to remove the filter cap

- 19mm wrench or socket

- 10mm wrench

- 13mm socket and extension

¤ - 6 quarts oil

¤ - Oil filter

RAMPS:

Necessary

for gaining ground clearance to lower or remove the belly-pan. Make sure that

they are rated for at least 4,000 pounds axle weight. Technically, you can crawl

underneath and remove the belly-pan without the use of ramps but this sure makes

things a lot easier. Cost is around $30-40. Available at Wal-Marts and nearly

all automotive supply stores. Necessary

for gaining ground clearance to lower or remove the belly-pan. Make sure that

they are rated for at least 4,000 pounds axle weight. Technically, you can crawl

underneath and remove the belly-pan without the use of ramps but this sure makes

things a lot easier. Cost is around $30-40. Available at Wal-Marts and nearly

all automotive supply stores.

TOOLS

19mm wrench or socket for removing the oil drain plug

10mm wrench for removing nuts on back brackets of the belly-pan

13mm sockets and extension for removing bolts on the belly-pan

Large Crescent-type wrench for removing the oil filter cap. Some people

are using a 36mm socket which fits over the large hex nut at the bottom of

the filter cap. Still others are using is simple band type filter wrench which

grabs and tightens onto the outside perimeter of the cap allowing it to be

loosened or tightened.

OIL:

Six quarts will be required. There is much misinformation

and contradictory information from VW as to exactly what the oil capacity is

supposed to be. As a precaution, check the oil level after you are about 1/2-way

through the 6th quart. Do not overfill.

VW officially recommends a multi-viscosity oil of 5W-40 or

5W-30 but unless you are in a severe cold area, 10W-40 or even 10W-30 will work

just fine. Check with your local VW dealership and ask what oil they put in

when they perform an oil change. Most are using 10W-30. The oil must carry an

API Service designation of "SL" (which nearly all major brands will meet).

Some people prefer to use a synthetic oil which has better

lubricating properties especially under extreme heat and pressure. The downside

is that is somewhat more expensive per quart, but makes up for it in longevity. And contrary what some unscrupulous

dealers may be telling you, Volkswagen Corporation has NOT required the use

of synthetic oil over the traditional "dinosaur" oil. Volkswagen has indicated

that it is a better, more preferred oil but its use is not required to maintain

your warranty status. Only you can decide if you want to spend the extra money.

Step-by-Step Oil Change Procedure:

Before you begin, you should know that the VW EuroVan chassis

from which the Rialta is based uses a sheet metal "belly-pan" underneath the engine

area on all VR-6 based engines. Some dealers and service centers may refer to

this as a "skid plate" but don't be fooled; it is merely sheet metal and very

light. It requires less than 5 minutes of extra work to remove the four bolts

and two nuts that hold it in place. The oil drain plug is accessible without removing

the belly-pan on all model years but in order to access and change the oil filter,

the belly-pan must be removed. This pan helps direct cooling air and keeps un-necessary

water and road debris from splashing all over the engine and other components,

in addition to quiet engine noise. In fact, the official name and description

from VW is "sound deadener".

You can optionally modify the belly-pan by creating a cut-out

in the area of the oil filter which will allow you to change the oil filter without

removing the belly-pan. See the modifications page entitled "Belly-Pan

Cut-Out" which is a Winnebago Service Bulletin in Adobe PDF format for complete

instructions. This modification will not void any VW warranty.

1. RAISE THE RIALTA

Drive your Rialta's front tires up on the ramps, put it in

park, put the emergency brake on, and shut off the engine. Remove the ignition

keys so that somebody doesn't accidentally start up the engine while you are working

on it. Place proper blocks behind the back tires to prevent the vehicle

from rolling back off the ramps. Don't skip the last part of this step --- be

safe and remember that you would probably not survive the weight of a Rialta coming

down on you if it rolls back down the ramps. Just think "what if" and be safe.

This is why I don't use a hydraulic jack to raise up the Rialta. If your ramps

are nearly maxxed out for their load limit, then before you crawl underneath you

may also wish to place some jack stands under the frame so that if one of your

ramps collapsed, then the vehicle would only fall onto the jack stand.

2. DROP THE BELLY-PAN

Even if you don't have to remove the belly-pan, some people

still like to completely remove it so that it gives them complete and easy access

to the oil filter plus a chance to visually inspect other components while looking

for loose hoses, clamps and brackets. Its also a good time to clean up any road

debris or residual oil film on the belly-pan and other parts.

There

are two 10mm hex nuts towards the rear of the pan where the back end of the belly-pan

changes into two hanger brackets. Remove both of these 10mm nuts. You will also

note that the rear hanger fits into a slot of the undercarriage. When you drop

the belly-pan, you can optionally choose to leave these hangers in the slots which

effectively serve as a pivot to allow the pan to drop down for service access.

Its a minor hassle to wiggle the hangers loose or to re-install them if you do

decide to completely remove the belly pan. I recommend that you completely remove

the belly pan as it will afford you an opportunity to get an unobstructed view

of the engine area and clean up any oil or fluid drips, not to mention the

ability to retrieve that nut, bolt, or wrench that you dropped through the engine

area. There

are two 10mm hex nuts towards the rear of the pan where the back end of the belly-pan

changes into two hanger brackets. Remove both of these 10mm nuts. You will also

note that the rear hanger fits into a slot of the undercarriage. When you drop

the belly-pan, you can optionally choose to leave these hangers in the slots which

effectively serve as a pivot to allow the pan to drop down for service access.

Its a minor hassle to wiggle the hangers loose or to re-install them if you do

decide to completely remove the belly pan. I recommend that you completely remove

the belly pan as it will afford you an opportunity to get an unobstructed view

of the engine area and clean up any oil or fluid drips, not to mention the

ability to retrieve that nut, bolt, or wrench that you dropped through the engine

area.

There

are four 13mm hex-head bolts pretty much in the four corners of the belly-pan.

You'll want to use a socket wrench with a long extension for removing the bolts.

There is one in each of the two front corners behind the bumper/grill area and

one on each side further back but still in front of the front wheels. There

are four 13mm hex-head bolts pretty much in the four corners of the belly-pan.

You'll want to use a socket wrench with a long extension for removing the bolts.

There is one in each of the two front corners behind the bumper/grill area and

one on each side further back but still in front of the front wheels.

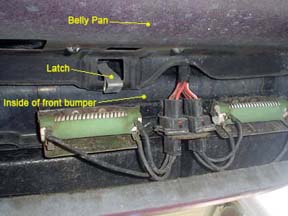

After you find and remove these four bolts, the

belly-pan will drop down about an inch or so -- it's a good way to know that you've

removed the right four bolts. The thing holding it in that position is a primitive

latch in the middle front of the belly-pan right behind the bumper and the two

rear brackets which fit into a slotted holder. Press and release this front latch

and the belly-pan will hinge downward from the hanger brackets at the rear. It

will drop down up front so be ready to catch it.

To completely remove the belly-pan, slide the entire thing

forward until the back brackets drop out of their slots. Now wrestle the pan straight

forward along the ground and out through the front until it is completely free

of the vehicle area. Contrary to what others may have said, the pan is only thin

sheet metal and not a skid-plate made of heavy metal. It probably weights about

20 pounds maximum. You can check the inside of the pan for any tell-tale evidence

of leakage and give it a little clean-up while in there.

3. DRAIN THE OIL

Raise the hood and remove the oil filler tube cap. Having the

cap off will help drain the oil faster and more completely. Put a proper capacity

pan underneath the area of the oil drain plug to catch the oil. This plug is located

in the side of the big black painted engine crankcase pan. You may want to put

down some cardboard or plastic under the whole area to save your driveway or ground,

because it will be a one-foot drop to the pan, and even a slight wind will cause

the oil flow to spray everywhere. Unscrew the oil drain plug using a 19mm wrench

or socket.

Let the oil drain COMPLETELY. Clean the area around where the

drain plug screws in and clean the drain plug itself making sure that the threads

are clean with no dirt or contaminants. Screw the drain plug back in being careful

not to strip the threads. It is inserted at a somewhat unusual angle, so be patient

and make sure you have it lined up properly. You should be able to tighten it

almost all the way by hand, and then just turn it a little more with a wrench

to make sure it is tight. Wipe off any oil drips around the oil drain plug, so

you'll be able to check for leaks once you add the new oil.

4. REMOVE THE OLD OIL FILTER

The

oil filter canister has a black cap which faces down at a slight angle. Keep in

mind the actual oil filter is an internal element, and the replacement filter

will not have the metal casing that is around most other commonly used "spin-on"

type filters. If you unscrew the cap, oil will start to leak everywhere so it

is best to first remove the bottom drain plug. Use a 6mm hex wrench to remove

a plug bolt to drain the oil from inside of the canister which avoids the big

mess of the oil spilling out when the cap is first loosened. With the oil drained,

use either a large Crescent type wrench or a 36mm socket on the bottom hex nut

to remove the cap. Alternatively you can use one of the band-type filter removing

tools. The

oil filter canister has a black cap which faces down at a slight angle. Keep in

mind the actual oil filter is an internal element, and the replacement filter

will not have the metal casing that is around most other commonly used "spin-on"

type filters. If you unscrew the cap, oil will start to leak everywhere so it

is best to first remove the bottom drain plug. Use a 6mm hex wrench to remove

a plug bolt to drain the oil from inside of the canister which avoids the big

mess of the oil spilling out when the cap is first loosened. With the oil drained,

use either a large Crescent type wrench or a 36mm socket on the bottom hex nut

to remove the cap. Alternatively you can use one of the band-type filter removing

tools.

With the cap removed, pull the filter element off the cap and

make a mental note of which end went in first. You can't really get it backwards

but by examining it now will make it easier when putting in the new one. Remove

the old O-ring from around the edge of the cap. A new replacement one should have

come with your new filter. You might need to use a pair of needle-nose pliers

to get a good grip on the old O-ring or use a small flat tip screwdriver to lift

it out of its groove. Use a clean rag to wipe out the inside of the cap and the

threads. Make sure you remove all dirt and small particles in the o-ring groove.

Put a little new oil on the new O-ring to lubricate it and then put it in the

same groove around the lip of the cap where you pulled the old one off. Make sure

it is in the groove or you'll end up with leaks. Do NOT try to re-use the

old O-ring as more than likely a slow dripping leak will occur.

5. INSTALL THE NEW FILTER

Special Note:On the filter for the AXK, 24 valve engine, the picture on the left below shows

how the filter looks out of the box. The "snout" may be removed before installation, as shown on the right,

otherwise the filter may get deformed when installed. Some of the cheap filters copied

this wrong and the stem isn't removeable, so it has to be cut off.

It's only there to hold the small o-ring for the drain plug on the filter cap.

(Click on photo for larger version.)

Properly

orient the correct end of the new filter in place in the cap, pressing firmly

until it snaps in place. Make sure to clean all of the threads on the cap. Take

the cap with new filter and new O-ring installed on it and careful screw it back

into place in the canister. It should turn easily all the way by hand. If not,

be careful -- you're probably stripping the threads on the cap. Properly

orient the correct end of the new filter in place in the cap, pressing firmly

until it snaps in place. Make sure to clean all of the threads on the cap. Take

the cap with new filter and new O-ring installed on it and careful screw it back

into place in the canister. It should turn easily all the way by hand. If not,

be careful -- you're probably stripping the threads on the cap.

After tightening it flush by hand, give it another very small

fraction of a turn with wrench, but don't over-tighten! Again, clean up the area

around the cap and filter canister so that you will be able to easily check for

leaks.

6. ADD NEW OIL

With the vehicle still up on the ramps, add five quarts of

new oil via the oil filler tube accessed from the top of the engine. Using an

in-expensive funnel helps keep the top of the engine clear of oil drips. You may

want to use an old rag or shop cloth and wrap around the area of the oil fill

tube just in case you get a little sloppy.

Put the oil filler tube cap back on, ensuring it is screwed

on tight. Check for immediate leaks around the oil filter canister area and the

oil drain plug. Tighten SLIGHTLY if there are leaks. Do not replace the belly-pan

just yet.

7. CHECK FOR LEAKS AND REINSTALL THE BELLY-PAN

With the belly-pan off and the vehicle still raised and secured

on the ramps, make sure you have added at least 5 quarts of new oil, and then

start the engine and allow it to idle in place for approximately two minutes,

just enough to warm up the oil and get it thoroughly circulated through the engine.

Do not crawl underneath the engine while it is running but bend over and examine

all around the drain plug and oil filter area. If you see any evidence of leakage,

immediately stop the engine and correct the cause of the leak.

Once you are satisfied that there are no oil leaks, shut off

the engine and replace the belly-pan. If you completely removed the belly-pan,

slide it back into place and engage the two back brackets into their holes. Now

lift the front edge of the pan and allowing it to slide forward slightly on the

back brackets. The holes in the back brackets will align with the two threaded

studs hanging down. The front end of the pan should snap over the latch in the

front which will temporarily hold it in place.

Replace and loosely tighten the two 10mm nuts at the rear brackets.

Replace all four 13mm hex-head bolts. You may want to loosely install all four

bolts before re-tightening them all. This allows for some slight movement and

adjustment that may be necessary to get all four bolt holes lined up. Don't forget

to fully tighten the two 10mm nuts at the rear brackets.

8. CHECK LEVELS AND FOR LEAKS (yes, again)

Remove the blocks from the back tires, start the engine, and

back off the ramps and move the vehicle to a flat level area. Put the Rialta in

park, set the emergency brake, and turn off the engine. Wait about two minutes

for all engine oil to re-collect in the bottom of the engine crankcase. Check

the oil level using the dipstick. For those not in the know, you need to pull

out the dipstick and wipe it off with a clean, lint-free cloth. Re-insert the

dipstick in the tube and make sure it is in all the way. Wait about 5-10 seconds.

Pull the dipstick back out and check the level. If it is within the acceptable

levels (see the EuroVan manual), do not add more oil.

If the level is too low, add a LITTLE more oil from the sixth

quart of oil, checking the level with the dipstick between each adding. On mine, I end up

around 5.4 quarts total. Do NOT

overfill because excess oil will be churned out in the exhaust and possibly destroy

the catalytic converter.

You should now be completely finished. Look around and make

sure you don't have any bolts or parts left over!

9. CLEAN UP

Now you're just left with clean-up. Make sure you dispose of

the used oil AND filter element properly. Let's keep them out of the landfills

and other improper dumpsites. Most AutoZones and other major auto supply stores

provide disposal of used oil and some will take the filter as well. Some municipal

garbage collection services will take your used motor oil if you pour it back

into the empty screw top containers that you used. This is an important step in

the process -- do the right thing or just have a professional change your oil.

SUMMARY

Make sure you make some kind of a log entry in your VW EuroVan

Maintenance Book that you changed oil and/or filter. Make a note of the odometer

reading and the date. If the need ever rises for a warranty claim, these log entries

should suffice and indicate that you took reasonable care of the vehicle as prescribed

by VW. Your warranty does NOT require that you have a VW dealer perform this simple

maintenance.

That's it. Although it might sound like quite a job for a first-timer,

if you've ever done an oil change before, most of this stuff should be second

nature to you. Now that you're done, pat yourself on the back for saving about

$100-150 some RV dealership charge for an oil change.

Now, done with your Oil Change on your 2000 EuroVan chassis

vehicle but want to reset your "Service Engine" light if it's flashing? See the

"Service Reminder Indicator" section on this

page.

Service Reminder Indicator (SRI)

The model year 2000 EuroVan included an automatic Maintenance Reminder system

that would flash the "Service OIL" or "Service INSP" light that

on the instrument cluster where the trip odometer miles are normally displayed.

This reminder will flash for about two minutes when you first start the engine

and then it will go out automatically. This is NOT an indication of a malfunction

but rather just a friendly service reminder that VW calls the "Service Reminder

Indicator" (SRI) display. It is interesting to note that only the 2000 EuroVan

has this feature and it is not found on any other model of car in the VW line

or any other production year. Apparently they figured out that it was a bad idea,

something it took the owners less than a week to come to the same conclusion.

Please note that this is NOT the "CHECK ENGINE" yellow icon that

may display in the center area of the instrument cluster. That "CHECK ENGINE"

display is an indicator that the engine computer has noted some type of fault

that needs to be diagnosed by a VW dealer.

When the VW dealer performs the oil change, one part of the procedure involves

hooking your vehicle up to the computer system which normally will download your

vehicle VIN and mileage information into a database that is supposedly available

at any dealership. In other words, you can be at any VW dealership and they can

tell via the database information if your vehicle received all the required maintenance.

However, there is a problem with VW dealers servicing Rialtas in that a lot of

them have the heavy duty hydraulic lifts required for the Rialtas installed at

the exterior of the service bays and therefore the computer hook-up may or may

not be available. Some dealers will manually reset the service mileage reminder

and some are totally ignorant of the procedure required.

And after 5 years of research, I was finally able to determine that the mileage

interval is hard coded into the Engine Control Module for illuminate the "Service

Oil" indicator every 7,500 kilometers (4,660

miles).

Here is the method to manually reset the SRI after performing a service:

-

Switch ignition OFF.

-

Press and hold down the trip odometer reset button at the lower right of

the instrument cluster.

-

Switch ignition ON and release the trip odometer reset button. It is not

necessary to start the engine; merely turn the key until the ignition is ON.

-

The trip mileage area now displays "Service OIL".

-

If trip odometer reset button is now pressed again, the display turns to

"Service INSP". Pressing the button again will cycle the display back

to "Service OIL".

-

When the reminder that needs to be reset (either OIL or INSP) is displayed,

turn button for setting the clock (at lower left of instrument cluster) to the

right. The display changes to "Service ----". That reminder is now reset.

-

The second reminder is unaffected unless it is displayed by pressing trip

odometer reset button and the clock button is turned right again.

-

Switch ignition OFF and back ON to resume normal display.

|