If for any reason you ever have a VW dealership or other automotive repair facility

work on your air conditioning unit in the VW portion of the cab, they will need

to know that any factory supplied sticker under the hood which relates to the amount

of refrigerant used in the system may need to be disregarded. The stock VW air conditioning

system may have been modified by Winnebago to include the overhead outlets in the cab

which blow air into the rear coach area.

If you are unfortunate enough to be faced with

a failed compressor on your Rialta, you have several choices. You can opt to pay

for an exact replacement from VW at their exaggerated prices. You'll end paying

nearly $2,000 and unfortunately have the same type of compressor that has been subject

to so much premature failure.

Another choice involves some retrofitting of a custom made valve

block made by one member of the Rialta Tech Group on Yahoo. Check the message files

for the subject thread. Supposedly this would allow the installation of a different,

more robust Sanden compressor.

And finally, yet another choice is to have your existing compressor

rebuilt by any of a number of rebuilding facilities. This usually results in the

cheapest total over cost but you are still at the mercy of the mechanic who is doing

the installation. Even in such cases, it is imperative that the mechanic follow

a strict set of guidelines in re-installing the rebuilt compressor. If anyone knows

of a good rebuild source, please let me know.

| 1. Why do I need to use an exact amount of

Freon? |

| 2. What is a "Liquid Charge", and why is

it dangerous? |

| 3. What causes clutch failure? |

| 4. What causes compressor failure? |

| 5. Why should I use R134a refrigerant? |

| 6. What does humidity have to do with my

air conditioner? |

| 7. Where does the "High Side" begin? |

| 8. Just what is this "Black Death"? |

| 9. What exactly does a drier dry? |

| 10. What is your position on flushing? |

| 11. What about system leaks? |

| 12. What does all this A/C jargon mean? |

| 13. What is a ton of refrigeration? |

| 14. How many different condensers are there,

and which can be flushed? |

| 15. What causes excessive clutch cycling? |

| 16. Why should I worry about ESD? |

| 17. Can compressors take all that heat? |

| 18. Does it matter what oil I use? |

| 19. What are the "Three laws of air conditioning"? |

| 20. What should be done when installing

a compressor? |

| 21. How does an automotive A/C system work? |

| 22. What about "Low Air flow"? |

| 23. My clutch (or switch) does not function,

what can I do? |

| 24. Is a little moisture in the system really

such a big deal? |

| 25. What are the basic A/C systems? |

| 26. How are clutch cycling switches different? |

| 27. Are your compressors compatible with

R12 or R134a? |

|

| Why do I need to use an exact amount

of Freon?

Today's A/C systems use

smaller amounts of Freon. No longer is it 2 to 4 lbs, but rather 18 to 38 oz.

With tight compressor tolerances and lubricant mixed with the Freon, the mixture

must be just right to enter the compressor as a mist. Wrong mixtures will either

under lubricate or slug the compressor causing premature failures. You don't

know how much liquid Freon is in a system so you should recover the old Freon,

evacuate and add the correct charge. Always check the OEM spec for the correct

charge.

Back to the FAQ

|

|

| What is a "Liquid Charge", and why

is it dangerous?

A "Liquid Charge" is any

charging of the A/C system using Freon which enters the A/C system in a liquid

state as opposed to a gaseous or Vapor state.

Warning! Charge A/C System with Freon

as Vapor, not Liquid!

If a charging hose is long enough you might get away with using liquid refrigerant

because the liquid will partially change to a gas in the hose. The odds are

not in your favor. More often you will freeze and shatter the compressors valves

when the refrigerant hits the valves as a liquid. This happens in mere seconds,

which is why we recommend charging the A/C system with the engine off.

Back to the FAQ

|

|

| What causes clutch failure?

Some common causes for

clutch failure:

1. Bearing failure.

2. Air Gap: Between the outer plate (hub) and the belt/rotor (.016 -. 030

inch) Note! Air gap varies with compressor type - check OEM specs.

3. Shorted Coil - Due to improper polarity or weak/burnt winding.

4. Low voltage at coil will cause coil to overheat due to slippage.

5. Locked Compressor: Excessive discharge pressure - Check for restricted

condensers, receiver/driers or an oil over charge

6. Belt is wrong type, wrong size, miss-aligned or loose.

Back to the FAQ

|

|

| What causes compressor failure?

Some common causes for compressor failures are:

LACK OF USE:

Compressors not run regularly will be starved for lubrication when they are

turned on. This causes excessive ware until the oil again reaches the compressor.

It's best to use the A/C once a week for a few minutes.

FAILURE TO FLUSH SYSTEM:

Compressors and hoses wear causing bits and pieces to mix with the oil. This

sludge gets into the compressor and can cause it to seize. Failure to properly

flush or using flush that leaves a residue is a primary cause of failure.

EXCESSIVE HIGH OR LOW

PRESSURE:

Condenser fans can quit due to bad connections or defective motor windings that

get too hot. This creates excessive head pressure and heat that can lock up

or damage a compressor. Loose connections at the coil can cause high resistance

and low voltage causing clutch slippage. Low refrigerant charge will cause lack

of lubrication getting to the compressor. Painting condensers will insulate

them from efficiently removing heat and increase head pressure in the compressor.

IMPROPER FREON OR OIL

CHARGE:

Compressors manufactured after 1990 have smaller capacity, therefore use less

refrigerant and oil and are extremely sensitive to inadequate amounts of oil.

The wrong type of oil may break down in high heat conditions. R134a systems

are more sensitive to lubrication than R12 systems. An over charge of oil can

clog the condenser, the orifice tube or expansion valve and starve the compressor

of oil. R12 systems use mineral oil and R134a systems use PAG or Double End

Capped PAG Oil (always check the OEM specs)

REFRIGERANT BLENDS

They can affect seals and O-rings, causing them to leak, swell or otherwise

deteriorate and it can happen relatively quick.

Back to the FAQ

|

|

| Why should I use R134a refrigerant?

R12 has the ozone depleting

chemical chlorine in it and has been replaced with a refrigerant known as R134a.

A boiling fluid absorbs heat and changes its state to a vapor. The expanding

vapor/gas has a lower pressure than the liquid and therefore lower temperature.

For heated air to be absorbed it must transfer to a cooler surface. The trick

is to find a liquid that boils at such a low temperature that the vapor is cold

enough to absorb the amount of heat generated inside an automobile. Freon-12

boils at -22º

F and its expanding vapor, in the evaporator core, absorbs the heated air circulating

around it. Freon-134a boils at about the same temperature as R12 and therefore

is a good replacement.

Back to the FAQ

|

|

| What does humidity have to do with

my air conditioner?

You're A/C unit works

to remove heat from the passenger area and in doing so it also removes moisture.

We are most comfortable when the relative humidity is closer to 20 percent than

90 percent, therefore the A/C system expends most of its effort wringing moister

out of the air. This is what air conditioning is all about - conditioning the

air. It's important to check the condensation drain at the bottom of the evaporator.

If you see clear water dripping from your car, when parked… it's a good thing…if

it's from the evaporator.

Back to the FAQ

|

|

| Where does the "High Side" begin?

Where ever the dam is located is the separation

point. We call it a dam because it has high pressure on one side and low pressure

on the other. This separator is call an Expansion Valve or an Orifice Tube.

Its job is to allow only enough refrigerant through to allow gas expansion in

the evaporator. By limiting the flow of gas it creates the high pressure back

to the compressor.

Back to the FAQ

|

|

| Just what is this "Black Death"?

Black Death, as it is

known by A/C techs, is a result from the breakdown of the refrigerant-lubricant.

This causes excessive wear inside the compressor and the excessive wear causes

a black residue that is actually a combination of solder flux from the condenser

and aluminum shavings from the old compressor. When this goop cools, it hardens

in the condenser. Repeated flushing will not remove it, however, when the system

is charged and running it liquefies, flows out into the liquid line and clogs

the orifice tube. With less refrigerant flowing past the orifice tube, the

compressor is starved of lubricant and will lock up. The only answer is to replace

the condenser.

Back to the FAQ

|

|

| What exactly does a Drier dry?

It's not the Freon!! It's

the oil in the refrigerant that absorbs moisture and holds debris in the system.

Replacing the drier or accumulator, in addition to evacuation, will assure better

performance.

Back to the FAQ

|

|

| What is your position on flushing?

Oil, sludge and debris

that is left in the system can clog the condenser, orifice tube or expansion

valve and damage the compressor. Flushing can remove excess oil and debris from

previous services. You do not want to add yet another charge of oil while leaving

an unknown amounts of oil in the system.

Caution!

Only flush a condenser

that capable of being flushed. The answer to question #14 deals with this problem

in greater detail.

Back to the FAQ

|

|

| What about system leaks?

At one time Freon was cheap and a 2oz. per year

leak was acceptable in a 4-5 lb. System. Today systems are smaller and 1/2oz

makes a big difference in performance. Good halogen leak detectors will show

most system leaks, under static conditions, however some will leak only when

the system is in operation. This is where the insertion of a florescent dye

can help find the leak. Note, to see the dye stain you need a UV lamp and the

leak has to be where the light can reach it. Most car manufactures approve the

use of trace dyes and some OEM's have been inserting trace dyes on the assembly

line. Dye can be inserted either when charging or when the system is charged.

The amount of dye used is less than 1/3 oz and remains in the system even if

the total charge is lost. The dye stains the oil not the Freon and only flushing

will remove it.

Back to the FAQ

|

|

| What does all this A/C jargon mean?

Glossary of Terms:

ACCUMULATOR: stores & filters Freon (on

Low side of system)

BTU: British thermal unit

AMBIENT AIR: outside air

CAPILLARY TUBE: gas filled temperature-sensing tube

CCOT: clutch cycling orifice tube that replaces the TXV

CLUTCH CYCLE SWITCH: evaporator temp controlled switch that cycles clutch

COMPRESSOR: pump that moves the refrigerant.

CONDENSER: heat exchanger-removes heat from refrig

DISCHARGE LINE: compressor outlet line

DRIER: filters refrigerant (located on High side of system)

EPA: Environmental Protection Agency

ESD: Electrostatic Discharge

EVAPORATOR: heat exchanger-removes heat from air

HEAT: anything above absolute zero has heat

HEAT EXCHANGER: device for transferring heat

LIQUID LINE: moves high-pressure liquid through system

MANIFOLD: connects suction & discharge lines to compressor

PAG: Polyalkylene glycol (lub used with R134a refrigerant)

PROM: Programmable Read Only Memory - use in computers

SUCTION LINE: between evaporator outlet and compressor

TXV: Thermostatic Expansion Valve - maintains evaporator

Back to the FAQ

|

|

| What is a ton of refrigeration?

One Ton of refrigeration is defined as amount

of heat (288000 Btu's) required to cause a change in state of one ton of ice

to one ton of water at 32 degs. F in 24 hours.

A/C units are rated by Btu/hour ratings. A one ton unit is rated as 12000 Btu's

(288000/24) The average factory installed auto A/C unit is rated at 1-3/4 ton.

Back to the FAQ

|

|

| How many different condensers are

there, and which can be flushed?

R134a condensers have

more fins/inch than R12 condensers and their fin diameters are smaller.( 6mm)

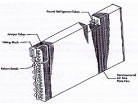

TUBE

and FIN - Oldest industry standard, 3/8-inch diameter round tube condenser.

Ok, for R12 but not recommended for R134a. This type of condenser is flushable. TUBE

and FIN - Oldest industry standard, 3/8-inch diameter round tube condenser.

Ok, for R12 but not recommended for R134a. This type of condenser is flushable.

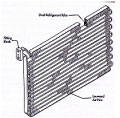

6

mm PICCOLO multi-flow: smaller, lightweight and more efficient than 3/8-inch

tube and fin and serpentine. Used in many domestic OE applications. This

type of condenser is flushable. 6

mm PICCOLO multi-flow: smaller, lightweight and more efficient than 3/8-inch

tube and fin and serpentine. Used in many domestic OE applications. This

type of condenser is flushable.

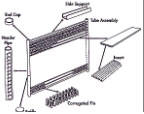

SERPENTINE:

All aluminum, more efficient than tube and fin, used on smaller imports where

space is limited. This type of condenser is not easily flushed, replacement

is recommended. SERPENTINE:

All aluminum, more efficient than tube and fin, used on smaller imports where

space is limited. This type of condenser is not easily flushed, replacement

is recommended.

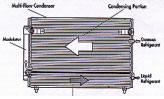

PARALLEL

FLOW: all aluminum, this efficient design breaks up flow into tiny streams that

give up heat more rapidly. This type of condenser is not flushable, replacement

only! PARALLEL

FLOW: all aluminum, this efficient design breaks up flow into tiny streams that

give up heat more rapidly. This type of condenser is not flushable, replacement

only!

PARALLEL

FLOW with SUB Condenser. Oval tube multi-flow and sub-condenser stacked up.

Refrigerant flows through the multi-flow into the drier (called a modulator)

then continues as a liquid into the sub-condenser. This type of condenser

is not flushable, replacement only! PARALLEL

FLOW with SUB Condenser. Oval tube multi-flow and sub-condenser stacked up.

Refrigerant flows through the multi-flow into the drier (called a modulator)

then continues as a liquid into the sub-condenser. This type of condenser

is not flushable, replacement only!

Back to the FAQ

|

|

| What causes excessive clutch cycling?

It's common to assume

low refrigerant is the cause for excessive clutch cycling and this often leads

to adding refrigerant and thereby overcharging the system. Most vehicles have

a compressor clutch cutout strategy based on an engine coolant temperature of

220 - 240 degs F. The vehicles computer relies on a coolant temperature sensor

to provide the signal for the compressor clutch decision and if the sensor reads

too high the clutch will cycle off. Cooling systems with a 50-50 anti-freeze

mix and the proper radiator cap should boil at around 275 degs, so the system

may not be boiling when the compressor cuts out. Check the actual coolant mix

and temperature by using an Infrared thermometer to check coolant temperature

and a Scan Tester to tell you what temperature the sensor is actually signaling

to the computer.

Back to the FAQ

|

|

| Why should I worry about ESD?

During the testing and

repair of computer controlled vehicles we come in contact with components that

may be damaged by ElectroStaticDischarge or static electricity. When installing new electronic

components, the part itself may have developed a charge from contact with the

package during handling; therefore you need to ground yourself to the body ground

of the vehicle. This is easily done by using a wrist strap that is available

at most electronic supply stores.

Back to the FAQ

|

|

| Can compressors take all that heat?

A compressor can take

the heat, but if there's a condenser airflow problem, overcharge, poor lubrication,

restriction, etc., the temperature can greatly rise and cause the compressor

to seize. Some vehicles have compressors mounted low in the engine compartment

and due to poor airflow the compressor can overheat and fail.

Back to the FAQ

|

|

| Does it matter what oil I use?

The moving parts of a

compressor must be lubricated during operation. The oil is absorbed into the

refrigerant that carries it through the compressor as a mist. An oil over/under

charge can damage the compressor. Compatibility of refrigerant oil is determined

by its ability to remain oil when mixed with the refrigerant and not become

separated by a chemical reaction. R12 systems use a non-foaming sulfur-free

grade of mineral oil (YN-9) formulated for that refrigerant and cannot be used

in R134a systems. R134a systems use either synthetic oil (PAG) YN-12 or Double

End Capped PAG oil.

Back to the FAQ

|

|

| What are the "Three laws of Air

Conditioning"?

Everything has heat except

at absolute zero (-460 degs. F)

LAW I: to refrigerate is to remove heat - the absence of heat is cold.

LAW II: heat is ready to pass to anything that has less heat - nothing can stop

the flow, you can only slow it down

LAW III: if a change of state is to take place there must be a transfer of heat

- If a liquid is to change to a gas it must take on heat.

Back to the FAQ

|

|

| What should be done when installing

a compressor?

Flush, with an approved

solvent, to Clean the system*

Replace the Accumulator/Drier

or Orifice tube

Replace manifold sealing

washers or O-rings

Use a Vacuum Pump (20+

minutes) to remove moisture.

Add the proper amount

and type of oil. Check OEM spec

Rotate compressor hub

12 times to oil the shaft seal

Place a strong external

airflow into the condenser

Check OEM specifications

for correct refrigerant charge

Charge with VAPOR refrigerant

and with A/C and engine off.

Do a leak test and

check voltage at clutch coil

Check belt tension

and alignment

Check system operation

at 1500 RPM and mid-blower speed

Use gauges to check

the system pressures.

*Only

if the condenser is the type that can be flushed.

Back to the FAQ

|

|

| How does an automotive A/C system

work?

All matter has a certain

amount of heat except at absolute zero (-460º

F). Ice cubes feel cool to the touch, but actually it just has less heat than

your hand. Heat is transferring from your hand to the ice cube. This is the

principle behind how an A/C cools the air in a car. Heated air is circulated

across a gas filled evaporator and is transferred to the refrigerant gas making

the air less hot. The heat-laden refrigerant then is drawn into the compressor,

is super heated by compression and forced through the condenser where the cooler

outside air takes the heat from the refrigerant. Its next stop is the expansion

device (TXV or Orifice tube), which meters refrigerant into the evaporator where

it expands into a gas and it starts over again.

Back to the FAQ

|

|

| What about "Low Air Flow"?

The complaint: "it

used to blow harder". Things to check are:

Low blower motor voltage

due to a poor ground

Blower wheel loose

on motor shaft

Defective blower relay

Air leak or obstruction

in air duct system

Air mode door directing

some of the flow to the heater outlet

Icing evaporator core

due to condensation.

Debris in evaporator

housing that blocks air circulation.

Obstruction at the

air return

Back to the FAQ

|

|

| My clutch (or switch) does not function,

what can I do?

Electronic circuits are

sensitive to voltage drops and operate in narrow voltage ranges. Many connectors

have small spade or pin type connections and are engineered to have near zero

resistance. If the connection is even slightly loose it will affect the voltage.

What may seem to be a defective component could be a bad connector. The problem

may be corrosion and careful brushing or using an electrical contact cleaner

may cure it. Many OEM harness connectors are available as replacement parts.

Back to the FAQ

|

|

| Is a little moisture in the system

really such a big deal?

Moisture causes internal

icing that obstructs the orifice tube or expansion valve. This can create excessive

high pressures and low cooling. The A/C system is a closed loop system so why

does it need a Drier to remove moisture? Here's how moisture gets into the system.

Refrigerant charged through service hoses not evacuated after being connected

to the system will have air and moisture in them. Hoses left uncapped while

replacing components allows moisture to enter. Refrigerant oil is hydroscopic

(water absorbing like a sponge) and left uncapped will have moisture in it.

Recycling machines with old filters will not remove moisture from incoming refrigerant.

Condensation created when the Low side of the system gets cold and then warms

up when the system is turned off is absorbed into the system through the hoses.

Systems low on Freon will pull moisture into the system when they go into a

partial vacuum.

Back to the FAQ

|

|

| What are the basic A/C systems?

ORIFICE TUBE

SYSTEM

Orifice tube systems use an Accumulator located in the Low side of the system

EXPANSION

VALVE SYSTEM

TXV systems use a Drier located in the High side of the system.

Back to the FAQ

|

|

| How are clutch cycling switches

different?

The clutch cycling switch

for R134a vehicles has been calibrated for the slightly higher pressure of R134a.

The threads, on the switch fitting, have been changed to metric to avoid connecting

to a R12 system.

Back to the FAQ

|

|

| Are your compressors compatible

with R12 or R134a refrigerant?

All of our compressors

are remanufactured with retrofitting in mind. Each compressor is remanufactured

with Nitrile or HNBR seals which allow the compressor to be installed in either

R12 or R134a refrigerant systems.

Back to the FAQ

|